EXTD 111: Final Project

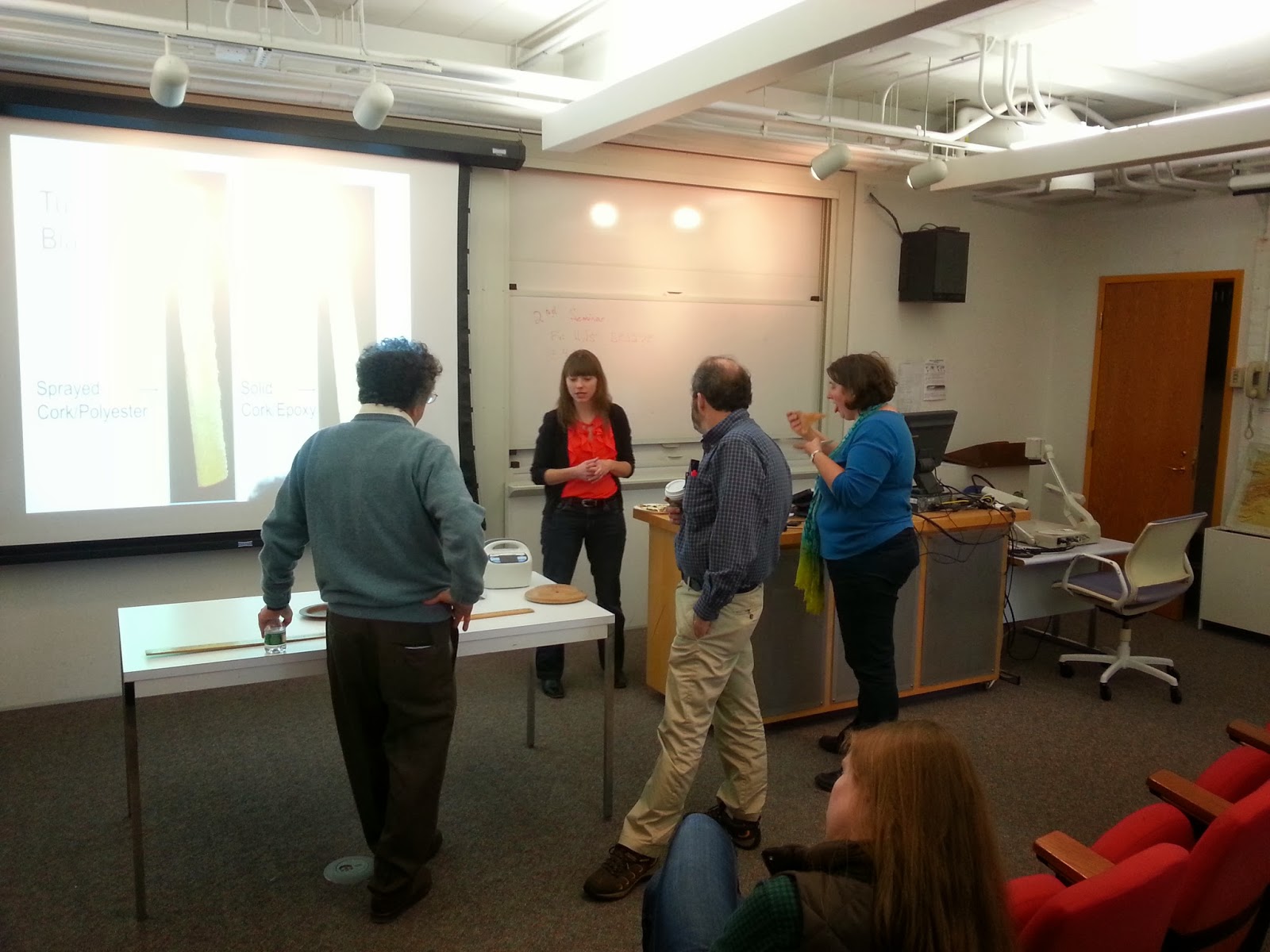

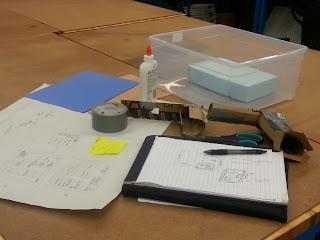

The Last Day of Classes Today! I still am trying to grasp that my first semester of college is coming to an end; it has been a challenge but fun. That said, I will miss my EXTD 111 class and am looking forward to EXTD 160 next semester. For the final project of this class, which is to be presented at the Engineering Exhibition today after class, my partner Gaby and I finished the CRI project we pursued. To recap, we took on the issue of attaching the pontoon to the rig and minimizing the trouble in putting on the far-end pontoon once the boat was in the water. We came up with the idea of a rotating mechanism that allows the pontoon to be flipped up or down as needed. Our final-final prototype is pictured left and you can read all about our design journey for the device HERE. Through the many many brainstorming ideas we had, the multiple calculations done and draft prototypes, the work was all worth it and I am very proud of our prototype. We cannot wait to receive feedback from