Go, Go, Lego Racer!

Objective: Discover the "magic" gear ratio to form a (relatively) fast Lego car that can carry a 1 kg weight in a race across a 4 m track.

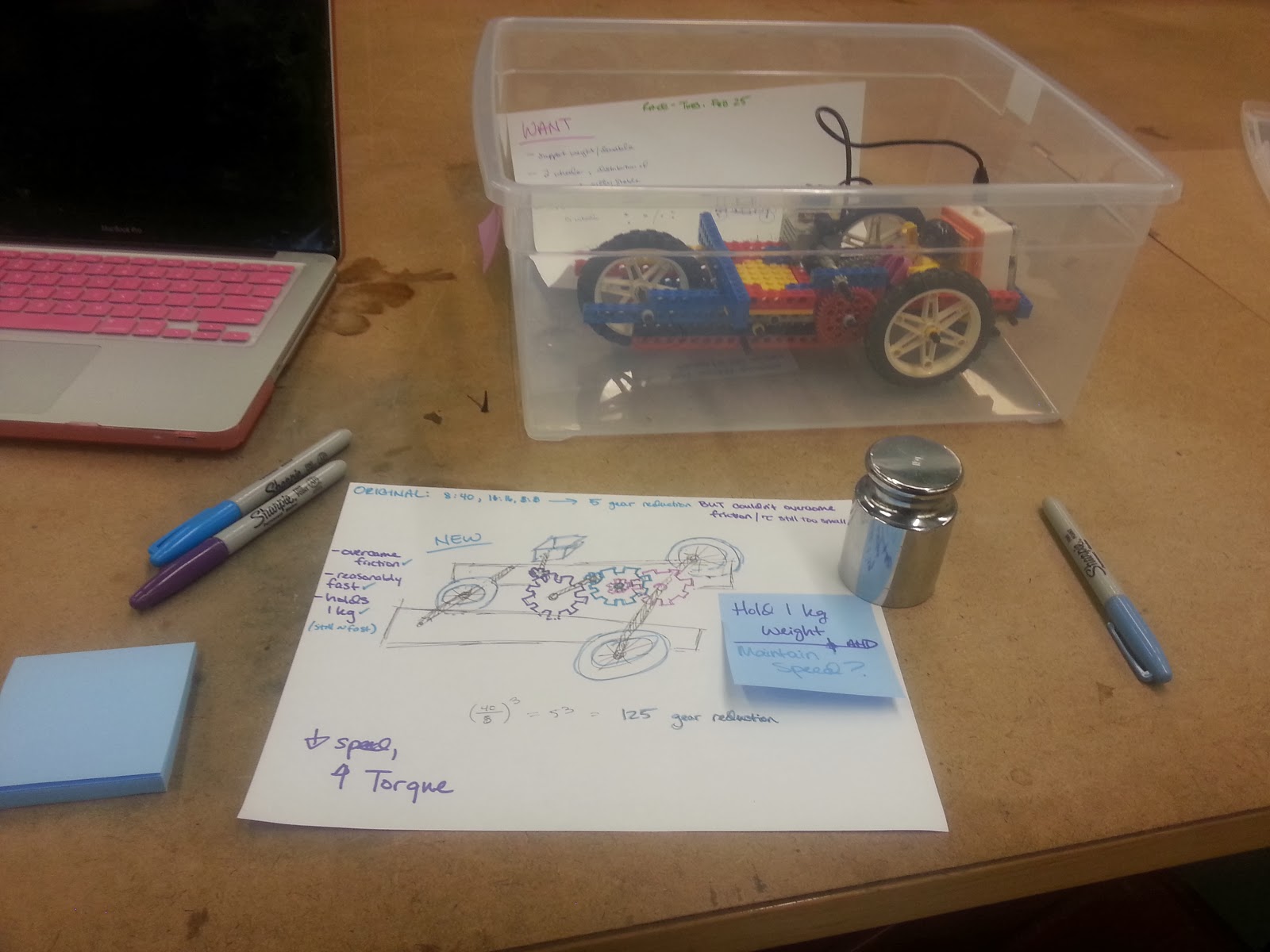

In our first iteration, we had trouble in getting our car to run. In our hands, the wheels would spin wonderfully but, once on the table, the wheels stalled. It then occurred to us what Professor Banzaert had said: "Torque is inversely proportional to speed." We finally figured out that, in order to produce enough power for the wheels -- or the torque -- to overcome the friction of the table (and later the 1 kilogram weight), we needed to decrease the speed.

NOTE: Power is torque (τ) multiplied by angular velocity (ω) or P = τ∗ω. Also, τ =|F|∗|r|∗cosθ (F = mass of weight times gravitational acceleration 9.8 m/s^2), which translates for gears into |F|∗tanθ and ω=v/r (v = velocity and r = radius of the wheel).

To decrease the speed, my partner and I had to increase the gear reduction ratio. Our first car had 3 pairs of 8-tooth gears spinning 40-tooth gears and, hence, the gear reduction ratio equated to (40/8)^3 or 1:125. It was built top-heavy and I put axes through the lower walls to help resist any pressure from the weight on top.

The First Trial

The car successfully completed the track with the weight on top. We create a triangular frame by having two back wheels powered by the motor and one disconnected wheel in front -- equidistant from the back two. The car completed the track in approximately 40-50 seconds -- which at the time was not terrible. Then, one group finished the track in 15 seconds and then another finished in 10 seconds.... 50 seconds started to not look so good. We needed to create a second car but still maintain our first in the case that something went awry.

The car successfully completed the track with the weight on top. We create a triangular frame by having two back wheels powered by the motor and one disconnected wheel in front -- equidistant from the back two. The car completed the track in approximately 40-50 seconds -- which at the time was not terrible. Then, one group finished the track in 15 seconds and then another finished in 10 seconds.... 50 seconds started to not look so good. We needed to create a second car but still maintain our first in the case that something went awry.

Design Iterations

After creating our "control car," my partner and I experimented with several gear ratios and created six different designs -- taking notes from each design and using them to create the next.

Test-and-Rebuild is known as a pretty inefficient method, but in continuing to test each iteration, I learned how gears operate and how to build a strong structure around them. If given more time, I would have recreated the sixth iteration, using the same gear ratio as well as a lighter, sturdier frame. From going to super heavy to really light, I noticed that there has to be a middle ground and, later on, I realized that a calculation of the force from the weight and legos would have made the process much simpler in the beginning.

NOTE: Power is torque (τ) multiplied by angular velocity (ω) or P = τ∗ω. Also, τ =|F|∗|r|∗cosθ (F = mass of weight times gravitational acceleration 9.8 m/s^2), which translates for gears into |F|∗tanθ and ω=v/r (v = velocity and r = radius of the wheel).

To decrease the speed, my partner and I had to increase the gear reduction ratio. Our first car had 3 pairs of 8-tooth gears spinning 40-tooth gears and, hence, the gear reduction ratio equated to (40/8)^3 or 1:125. It was built top-heavy and I put axes through the lower walls to help resist any pressure from the weight on top.

The First Trial

The car successfully completed the track with the weight on top. We create a triangular frame by having two back wheels powered by the motor and one disconnected wheel in front -- equidistant from the back two. The car completed the track in approximately 40-50 seconds -- which at the time was not terrible. Then, one group finished the track in 15 seconds and then another finished in 10 seconds.... 50 seconds started to not look so good. We needed to create a second car but still maintain our first in the case that something went awry.

The car successfully completed the track with the weight on top. We create a triangular frame by having two back wheels powered by the motor and one disconnected wheel in front -- equidistant from the back two. The car completed the track in approximately 40-50 seconds -- which at the time was not terrible. Then, one group finished the track in 15 seconds and then another finished in 10 seconds.... 50 seconds started to not look so good. We needed to create a second car but still maintain our first in the case that something went awry.Design Iterations

After creating our "control car," my partner and I experimented with several gear ratios and created six different designs -- taking notes from each design and using them to create the next.

Test-and-Rebuild is known as a pretty inefficient method, but in continuing to test each iteration, I learned how gears operate and how to build a strong structure around them. If given more time, I would have recreated the sixth iteration, using the same gear ratio as well as a lighter, sturdier frame. From going to super heavy to really light, I noticed that there has to be a middle ground and, later on, I realized that a calculation of the force from the weight and legos would have made the process much simpler in the beginning.

It seems that by the end you had a good understanding that both structure and gear ratio matter just as much as the other! Great car!

ReplyDelete